Rail-Less Metal Roof Solar Mount

The DirectAttach™ Solution for Standing Seam and Exposed-Fastened Metal Roofs

Get Your Solar Mounting Checklist

Use it to guide your next project through layout, design, cost, project logistics and aesthetics.

Designed for coastal communities and other high-wind zone areas!

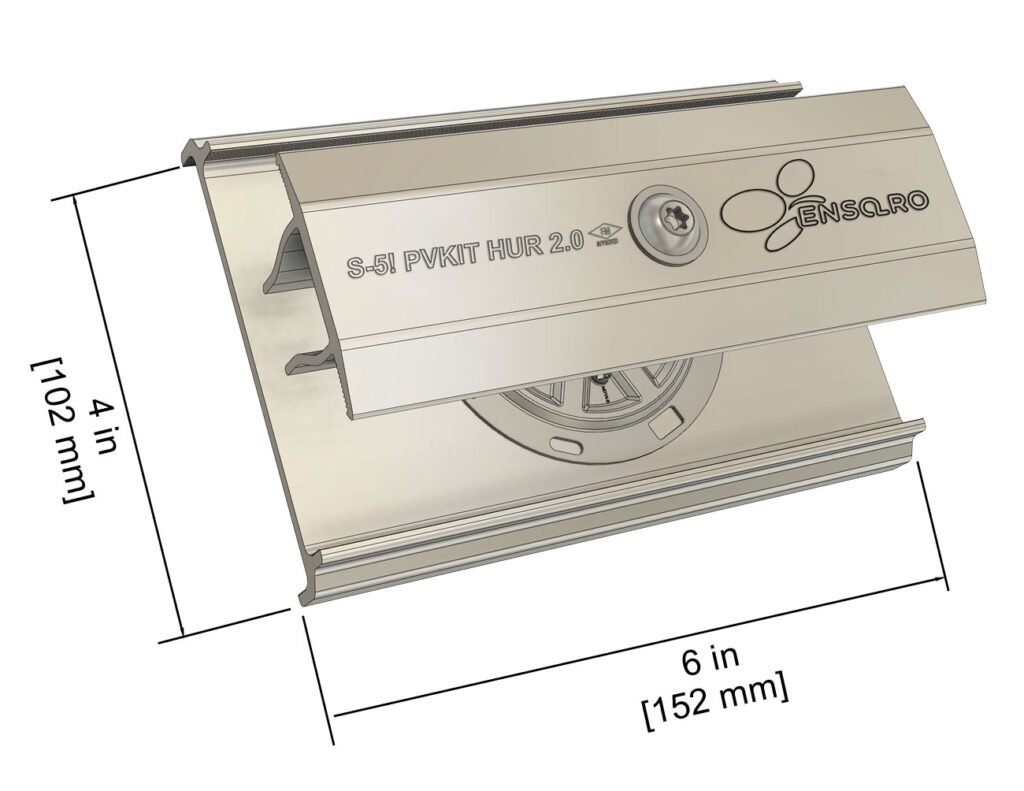

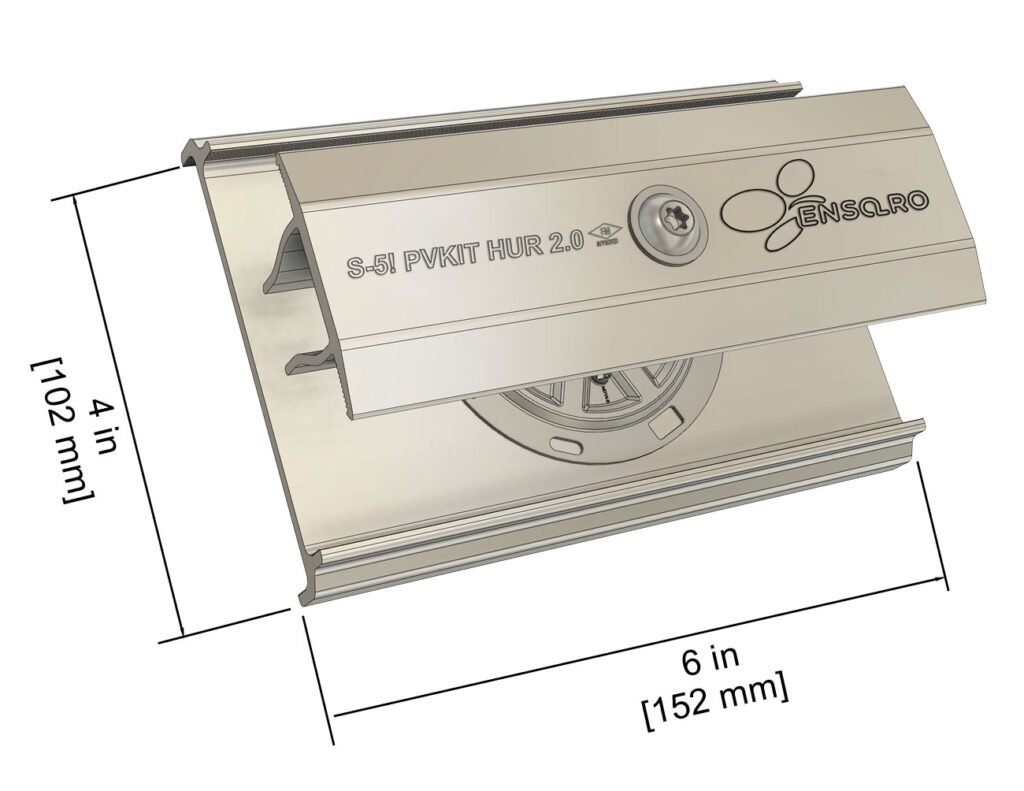

An enhanced version of the original PVKIT® rail-less, solar mounting solution for metal roofs, S-5-PVKIT HUR 2.0 (High Uplift Resistance) is a first-of-its-kind PV mounting system specifically designed for high wind uplift performance of installed solar panels and is approved to FM 4478.

Designed to withstand extreme wind uplift forces such as hurricane forces, as well as heavy snow loads, the 6" (152 mm) length of the overhead grabs, providing a larger contact area with the top of the PV module’s frame. This prevents it from releasing as the module frame bows under extreme forces. A new contact surface design and angle also increases the grip on the frame. The new baseplate design further prevents the module from bending and disengaging under high wind uplift forces. Together, these features improve the structural integrity of the module-to-roof attachment.

Pricing Per Assembly:

(EdgeGrab & MidGrab)

Minor Box: $23.60 Qty: 72 (Edge) 64 (Mid)

Master Box: $22.82 Qty: 72 (Edge) 64 (Mid)

*Pricing above is per grab in USD. Prices vary based on region and other factors. Pricing improves with order quantity. Broken boxes may be subject to handling charges. Call your Authorized S-5! Distributor for current pricing.

S-5-PVKIT HUR 2.0 Features

• Increases wind uplift resistance of mounted solar modules - 150 psf rating

• Gravity (snow) load strength - 120 psf rating

• Reduces added dead load of mounting components

• Improves load distribution by 25% reducing point loads

S-5-PVKIT HUR 2.0 Works for the Following Roof Type:

Exposed-Fastened

Standing Seam

Corrugated

S-5-PVKIT HUR 2.0 Components

Compatible S-5! Bracket

Attachment for exposed-fastened roofing. See specific product pages for critical dimensions to ensure correct bracket selection.

(Pictured: Protea™ Bracket for exposed-fastened, trapezoidal rib metal roofing. Visit our bracket overview page to view additional attachment solutions.)

Compatible S-5! Clamp

For use on standing seam profiles. See individual pages to select the best attachment solution for your metal roof profile.

(Pictured: S-5-S. Visit our clamp overview page to view additional attachment solutions.)

Have More Questions?

Submit your information by clicking the form below, and we’ll get back to you almost immediately.

FAQs

What spacing should be used with S-5! clamps for PV assemblies?

The following suggestions assume a determination has been made that the roof to which the S-5! clamps will be attached is structurally adequate. Any loads imposed on the S-5! clamps will be transferred to the panels. Panel seams must have sufficient flexural strength to carry these loads. Panels must also be adequately attached to the building structure, and the structure must be sufficient to carry these loads. The makers of S-5! clamps make no representations with respect to these variables. It is the responsibility of the user to verify this information or seek assistance from a qualified design professional, if necessary.

The key to frequency and spacing of attachment points for PV is to distribute loads to the metal standing seam panels in a manner consistent with the intended distribution of loads from the roof panels into the building structure. With very few exceptions, the attachment of a single S-5! clamp (even the “Mini”) to the seam will be stronger than a single point of attachment of the seam to the building structure. Hence, the “weak link” is not the S-5! clamp, but the attachment clips that hold the metal panels to the building structure or the beam strength of the roof panel seam itself.

The most conservative approach to the spacing/frequency of PV attachment to the roof is to determine the spacing/frequency of the roof’s attachment to the building structure; then duplicate it at minimum. Determining panel attachment spacing in one axis is very simple: A standing seam panels’ attachment will be made using concealed hold-down clips within the seam area of the panel. So, in that axis, the clip spacing is the same as the seam spacing. The location of the clips along the seam (in the other axis) can be determined by a) consultation with the roof system manufacturer or installer, b) checking from the underside or, c) close examination from the topside along the seam. There will usually be a slight, but detectable, deformation of the seam at the clip location visible from the roof’s topside. Many standing seam roofing systems are installed on “pre-engineered steel” buildings. The attachment spacing in that industry is typically 5’-0” and is readily apparent by inspecting the structural purlins to which the panel clips are attached from the roof underside (interior of the building).

If the panel clips are spaced, for instance, 5′-0″ on center along the seam, then use the 5′-0″ dimension as a maximum spacing for the S-5! clamps. (S-5! clamps may also be spaced at closer centers, but not wider.) When modules are direct-attached (without racking) in landscape orientation, this spacing dimension is dictated by the smallest dimension of the PV frame. Using the roof panel clip spacing as a maximum spacing template for S-5! clamps is a sound practice whether the PV modules are attached directly to S-5! or to a racking system, which is in turn, attached to the S-5! (and panel seams). To evenly distribute loads, it is also necessary for each seam to be involved in the finished assembly. Thus, every time a seam is traversed, it should be attached. Such an attachment scheme should evenly distribute wind loads into the building structure through the panels and their attachment, as intended in the original roof construction assembly.

Please note, these are only suggestions. Wind dynamics are complex, and S-5! advises review by a qualified licensed professional who understands wind effects and metal roof design and construction.

Can S-5! clamps be used as a grounding path to the roof?

A question we are asked frequently at S-5! is whether or not our clamps are an approved path for grounding the solar array to the roof. The S-5! PVKIT / S-5! standing seam clamp assembly is a UL2703 listed bonding device. While the listing covers carrying a ground path from PV panel to PV panel, the clamp to the roof panel material is not included in this certification.

On an individual basis, some independent racking companies have worked with certification labs to verify the clamp-to-roof connection and its reliability as a bonding path. For instance, IronRidge has found S-5! clamps provide a reliable bond path between the clamps and the roofing panels beneath the array. This rating is included in their racking systems UL2703 listing. Please see page 4 of the links:

How much load will S-5! clamps hold?

The answer to this question varies with the load direction, the seam profile, the roof material and the clamp model. We have conducted hundreds of tensile load tests parallel to the panel seam and on various gauges and profiles, and we have tabulated the results for your convenience. See Load Test Results for more information. In this parallel load direction, any loads introduced into the clamp will accumulate into the point of fixity. Panels must be adequately attached to resist these loads.

Should I be concerned about metallurgical compatibility?

Metallurgical compatibility is extremely important. Incompatibility can cause rapid galvanic corrosion and void material warranties. S-5! aluminum clamps are totally compatible with painted or unpainted G-90 galvanized steel, bare or painted Aluminized, Galvalume, Zincalume, ZincalumePlus, Acrylume Galvalume Plus, Galfan and Galvanneal steel. They are also compatible with aluminum (painted, bare or anodized), titanium-zinc (VM & Rheinzink) and stainless steel. Our brass clamp is compatible with copper roofing.